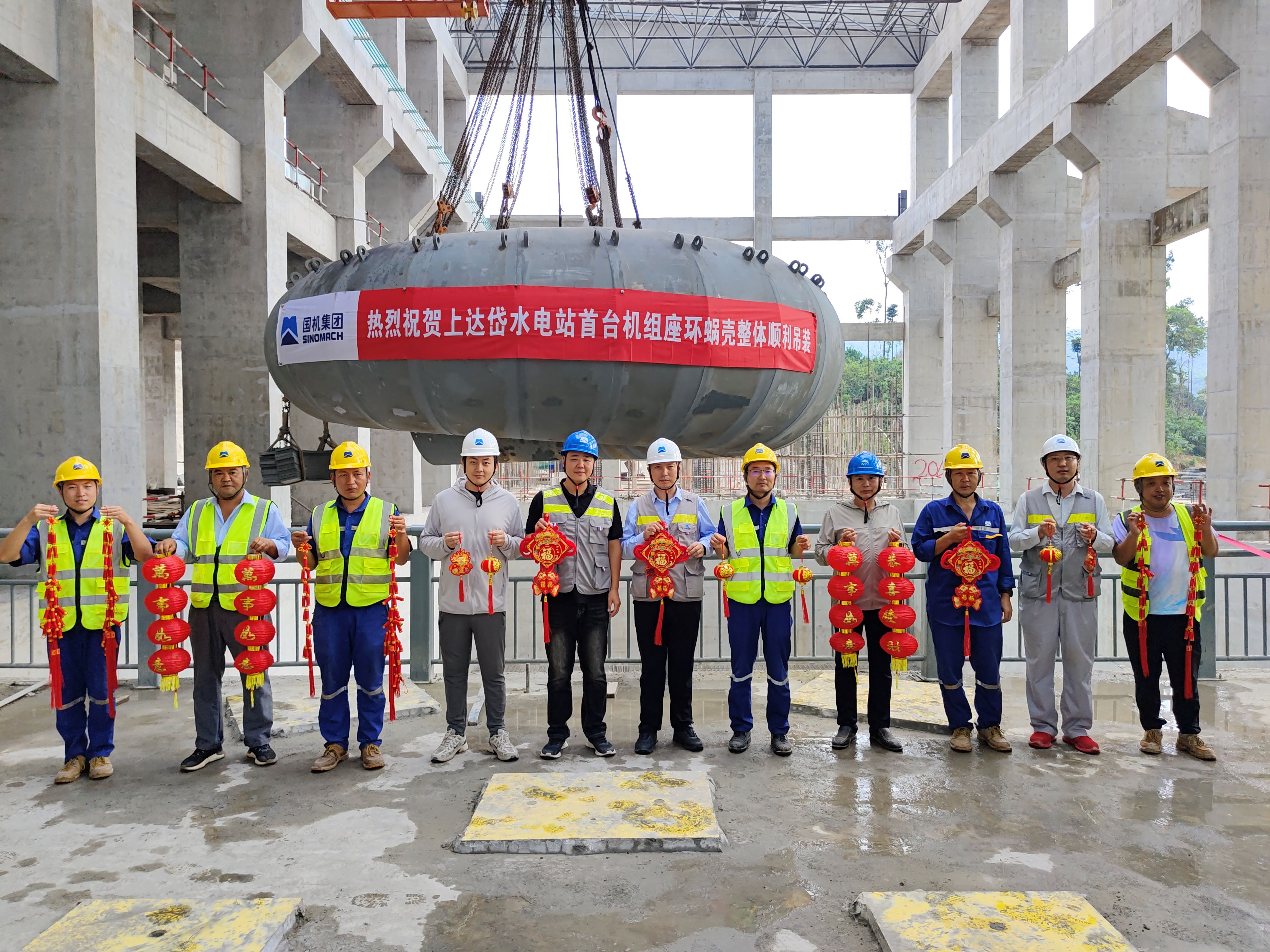

On January 26, the stay ring and spiral case for the first generating unit of Cambodian Upper Tatay Hydropower Station, constructed by China National Heavy Machinery Corporation (CHMC), was successfully hoisted into position. This achievement marks the completion of the first major milestone in 2025 and signifies that the installation of embedded electromechanical equipment has entered an intensive period.

To further shorten the critical path of project construction, the working team of Cambodian Upper Tatay Hydropower Co., Ltd. (CUTHL) organized extensive discussions with designers, supervision engineers, manufacturers, and installation contractors. Through optimizing the installation sequence, the team shifted the assembly and welding of the stay ring and spiral case from the pit to the assembly bay, ultimately reducing the critical path duration by 35 days.

The stay ring and spiral case of the generating units of Upper Tatay Hydropower Station has a maximum diameter of approximately 11.56 meters, a height of about 3.2 meters, and a total weight of around 64 tons. As the largest component to be hoisted during electromechanical installation, it serves as a critical flow-passing component of the hydropower generating unit. Its function is to guide water flow evenly into the turbine chamber, driving the rotation of the turbine and converting potential energy of water into mechanical energy.

Prior to the hoisting operation, the working team conducted on-site safety and technical briefings, as well as detailed explanations of the hoisting operation, ensuring all personnel involved were fully aware of the work requirements. During the hoisting process, the working team and supervision engineers monitored on-site to ensure strict compliance with the predetermined plan and technical specifications.

The successful installation of the stay ring and spiral case provides strong assurance for the on-schedule power generation of the first generating unit of Upper Tatay Hydropower Station.