As the foundation of national economic construction, metallurgy is typically a symbol of national strength and industrial development. Over the past 30 years, China National Heavy Machinery Corporation (CHMC) has committed itself to the construction and development of the metallurgy industry based on a professional attitude, excellent technical talents and advanced management mechanisms. By means of introducing technology, joint design and cooperative manufacturing, CHMC has provided dozens of steel giants both at home and abroad with high-quality and complete sets of equipment, project management and general contracting services.

As the project’s general contractor, CHMC has engaged in cooperation with foreign partners to design and manufacture 1,200-2,300 mm specifications of slab caster equipment and molten steel refining equipment for Phase II of Shanghai Baoshan Iron and Steel Group Corporation, Anshan Iron and Steel Group Corporation, Wuyang Iron and Steel Co., Ltd., Panzhihua Iron and Steel Co., Ltd., Benxi Iron and Steel Co., Ltd., Kunming Iron and Steel Co., Ltd., Anyang Iron and Steel Co., Ltd., Jinan Iron and Steel Group Corporation, Beixing Special Steel Group Corporation, Tonghua Iron and Steel Co., Ltd and others. Among the companies mentioned above, Panzhihua Iron and Steel Co., Ltd.'s 1,350 mm slab caster complete set of equipment won First Prize at the National Scientific and Technological Progress Awards and the Special Prize for Scientific and Technological Progress from the former Ministry of Machine Building.

CHMC has provided design, manufacturing, installation and commissioning of the 15-300 ton converter and RH vacuum treatment equipment for Jinan Iron and Steel Group Corporation, Shanghai Baoshan Iron and Steel Group Corporation, Tonghua Iron and Steel Co., Ltd., Panzhihua Iron and Steel Group Corporation and Great Wall Special Steel Co., Ltd.

CHMC has provided 300-2,000m3 of blast furnace equipment for Baotou Iron and Steel Co., Ltd. and Benxi Iron and Steel Co., Ltd. CHMC has cooperated with Japan Nippon Steel and was contracted to provide a 320 ton torpedo-type hot metal mixer for a 4,063m3 blast furnace and converter used by Shanghai Baoshan Iron and Steel Group Corporation.

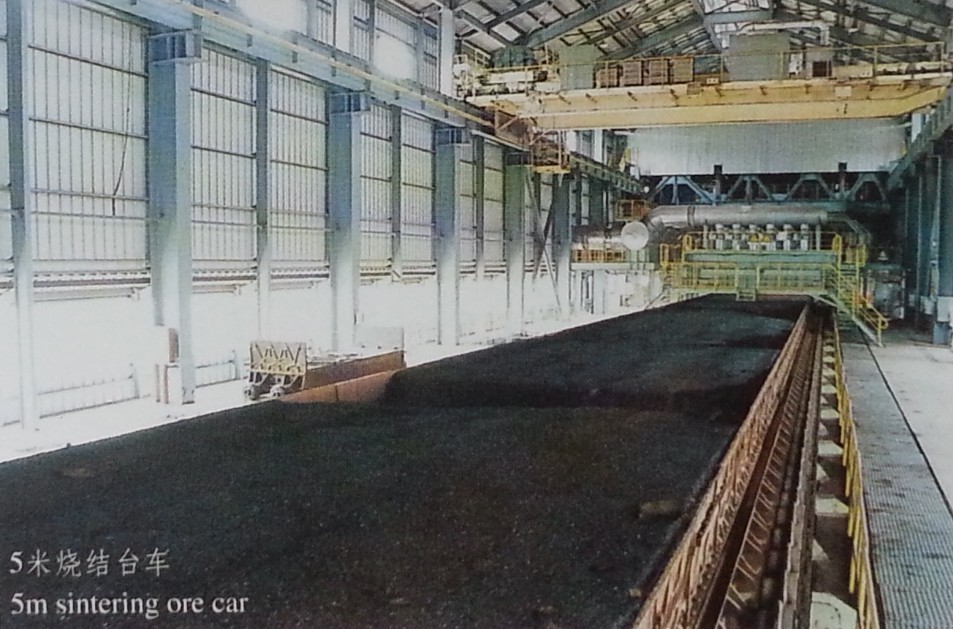

CHMC has engaged in cooperation with Hitachi Shipbuilding Corporation of Japan, and has been contracted to complete the design, manufacturing, installation and commissioning of 450m2 of sintering machine complete sets, with the equipment set to be used on Phase II and Phase III of the Shanghai Baoshan Iron and Steel (Group) Corporation projects. It has also taken on general contracting services for the design, manufacturing, installation and commissioning of dozens of sintering complete sets of equipment, including a 300m2 sintering machine for Ma'anshan Iron and Steel Co., Ltd., a 265m2 sintering machine of Anshan Iron and Steel Group Corporation, a 132m2 sintering machine of the Tianjin Iron Plant, a 90m2 sintering machine used by Handan Iron and Steel Co., Ltd. and Xiangtan Iron and Steel Co., Ltd., and a 75m2 sintering machine used by the Echeng Iron and Steel Plant.

CHMC has engaged in cooperation with professional coking companies in Japan and Germany, and has signed contracts for the design, manufacturing, installation and commissioning of a complete set of equipment for Phase II and Phase III of the 4 x 50 hole 6 m coking project of Shanghai Baoshan Iron and Steel (Group) Co., Ltd. In addition, CHMC introduced 7.63 m coke oven mobile machinery for Taiyuan Iron and Steel Group Corporation and took on responsibility for 6 m coking equipment projects for the Wuhan Iron and Steel (Group) Corporation and the Tianjin Third Gas Plant, as well as 4.3 m coking equipment for Chengde Iron and Steel Co., Ltd., Hefei Iron and Steel Co., Ltd. and other companies. CHMC took on general contracting services for the design, supply, installation and commissioning of coking projects at Pakistani Steel Mills.